Flying Without a Net

When the world gets crazy and chaos reigns, I retreat.

Either I withdraw deep within my mind and enjoy the rich inner life I have created there or I physically retreat to the studio and entertain myself to my heart's content.

These things make me happy.

It should come as no surprise I have my own way of doing things.

With weaving, I have an idea of the things I would like to make.

As I encounter inspiration, I rate it in my head along the lines of one day, sooner rather than later, or must clear a loom to do it NOW.

I maintain two queues. One is a binder where I keep paper patterns from kits I have purchased or paper magazines. The other is on Ravelry where I create a digital project long before I ever start it.

Ravelry is my primary queue.

Once a project is created, I upload the inspiration, whether it is a photo or a draft. I add notes indicating whether it should be tea towels, fabric for clothes, a baby blanket, or whatever. I usually have a good idea of the size thread I will use and sett. If I am particularly excited about it, I will do all the math associated with it and wait until a loom becomes available. 99% of my projects evolve in this manner.

When I had just the three Macomber floor looms, I good deal of thought was required to organize and prioritize the queue based on which projects were appropriate for which looms.

For example, at 56" wide, the Beast is the most versatile loom I have. EVERYTHING can be woven on him from 10-inch wide scarves to 100-inch wide coverlets (using double width weaving), as well as 4-foot wide rugs.

At the other end, the 24-inch Meg requires a good deal more thought, as she is limited by her weaving width and the number of heddles she has per shaft. Uninstalling harnesses and moving heddles from one to another is time consuming, and I would prefer not to do that if at all possible. So, while there are 24" wide patterns that would physically fit on Meg, I would not be able to weave them because the threading pattern may require more heddles on one or more shafts than she typically carries. Instead, I will bump that project up to the 32-inch Lil Miss who has more heddles per harness.

I have had three looms for a while now and none of them has remained bare for more than a week, if that long.

Moreover, all three looms received attention. It is not unusual for me to cycle among all of them in a day or weekend; however, when something needs to be done, I will spend a few days, maybe even a week, to see a project to completion.

When my friend Callise sent me the link for Evangeline in Louisiana, I was not looking for another loom, Macomber or otherwise. I was content with my three. I was happy and fine.

However, after a bit of consideration, I decided the loom was too close, at least to my mother's home, the price was too good, and I could always re-home it, if I decided I did not want to keep her.

Of course, now that I have her in the studio upstairs and the first round of upgrades are completed, she is definitely staying.

Monday afternoon, I received a package from Macomber with a lamm depressor kit, complete friction brake kit, beater bumpers, and lamm depressor pin for Meg.

The husband was to install everything for me, but he was not feeling well when he returned from work. I gave him a pass.

Initially, I thought I would just wait until he felt better, but I bought myself a little Black & Decker 12-volt cordless drill a few months ago.

I decided to try my hand at swapping out the end pieces to convert the sectional beam from a ratchet to a friction drum.

Five minutes later...

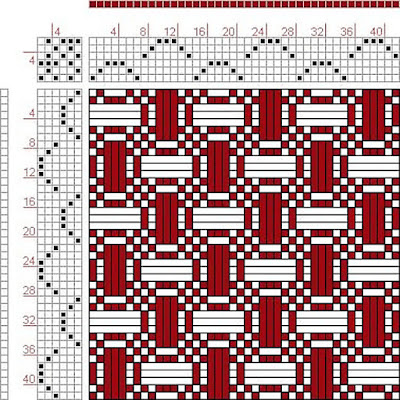

Checking the queue again, I found I had a pattern that I had not realized called for six-shafts.

I did a quick tally of the total number of heddles required per harness and decided it was a go.

Now, this is out of character for me.

I much prefer to study things and think them completely through before I begin.

Instead, I shrugged and decided I had a brief opportunity to put something totally different than what I normally do on this loom, and I ran with it.

I did not do specific calculations to ensure the stripes were even and equal and well spaced out or anything. I lined up the cones in colors that I liked and decided how wide to make the stripes while at the warping square.

I did not calculate how many yards of each color I needed, then weigh the cones to determine whether I had enough of each color. I even ran out of the yellow...

It was fine.

It did not matter.

I decided this warp was going to be whatever it was going to be...all thirteen yards of it.

Moreover, because the threading was not *odd, even, odd, even* throughout, the safety net of plain weave was not even an option, if the threading draft did not work out.

That was HUGE.

I did not bat an eye, though, I just continued. Worst case scenario I would have to cut off the sample and re-thread the heddles. I could live with that.

In fact, I can live with this just fine:

Comments